PROGRAMMABLE MUCIN EXTRACTOR

CHAPTER EIGHT: VALORISATION

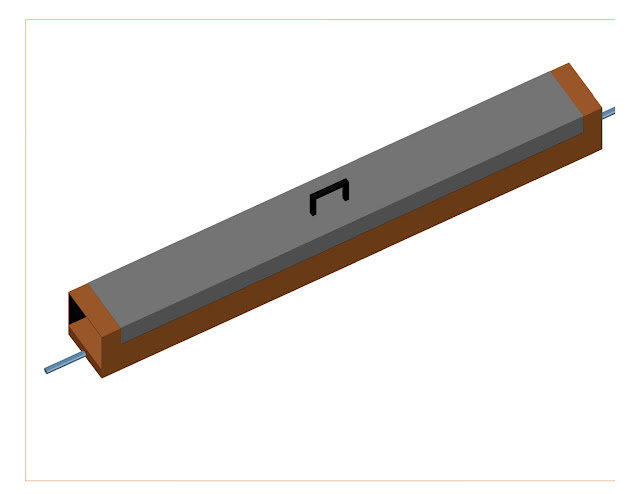

The Programmable Mucin Extractor

This is the latest of my designs. On the 6th of June 2021, I was contracted by an Ireland-based company; Valor Africa, an agricultural sustainability and valorization company, to develop and design a machine that is capable of systematically extracting slime from the African snail, Achatina fulica. The machine has since been moved in for fabrication, where I am closely monitoring and supervising the process of its fabrication.

Abstract on The Machine

The Programmable Slime Extractor is the very first of its kind, and hence will be patented to Valor Africa as a company-developed machine. The machine will incorporate the use of PLUs to run the processes of the machine. First the snails are prepared and loaded unto the screen/basket, in the machine. Then programmable valve-controlled nozzles are made to open and spray cold (done by a chiller), disinfected (done by a UV system), and ozonized (done by an electric ozone generator) water on the snails to activate them. Next a chemical is applied similarly on the snails, forcing them to excrete slime. At the final stage of the operation, the slime is vibrated off their bodies and flushed down unto a funnel by another water shower, and is finally collected by a container beneath. The collected slime is then concentrated in a lab to remove excess water. This product is an essential raw material for pharmaceutical/drug and cosmetic industries.

NB: The snails are still very much alive after this operation, and still edible.

As the machine is one that handles delicate substances that will be ingested directly into the human body, special care is given to its design especially in the aspect of machine material and reduced product handling and contamination.

As was said in the F-CAD Drawings blog preview, some of my designs are actually produced after the CAD designs. below are photos of work in progress for the fabrication of the Extractor.

_page-0001.jpg)

Comments

Post a Comment